rockwell hardness test slideshare|rockwell hardness scale examples : agencies Stanley Rockwell invented the Rockwell hardness test to provide a fast, non . Previsão de Ondas: Modelo Wavewatch III pelo Surfguru. Previsão Atmosférica: NOAA GFS (Global Forecast System) Tabela de Marés: Marinha do Brasil | xTide. Estação Meteorológica: METAR | Weather Underground. Saiba mais sobre a .

{plog:ftitle_list}

webIn 509 B.C.E. Rome became a republic ruled by the Senate (wealthy landowners and elders) and the Roman people. During the 450 years of the Republic, Rome conquered the rest of Italy and then expanded into France, Spain, Turkey, North Africa, and Greece. Rome became very Greek -influenced or “Hellenized,” and the city was filled with Greek .

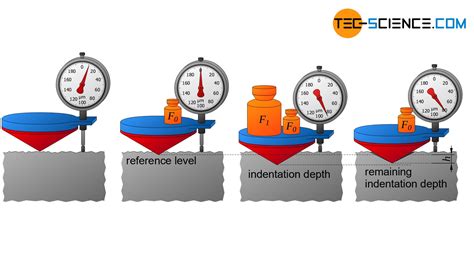

Rockwell hardness testing measures the additional depth of a heavy load indenter beyond the depth of a previously applied light load. Both tests provide standardized .Rockwell hardness testing involves indenting a material with either a .

Stanley Rockwell invented the Rockwell hardness test to provide a fast, non . Rockwell hardness testing involves indenting a material with either a diamond or steel ball indenter under a minor preload and then a major load. The difference in indentation depth is used to determine the Rockwell . Stanley Rockwell invented the Rockwell hardness test to provide a fast, non-destructive method for determining the success of heat treatments on ball bearings. There are two types of Rockwell tests that use different .Quantitative Hardness Test. A small indenter is forced into the surface of a material to be tested, under controlled conditions of load and rate of application. The depth or size of the resulting .

The Rockwell hardness test is the industry standard measuring system used to determine how resistant a material is to another object. Hardness is defined as a material’s resistance to permanent indentation.The Rockwell hardness test measures the hardness of a material by applying two loads to a diamond or steel ball indenter that is pressed into the surface of the material. The hardness number is determined using the formula HR = E - e, . Rockwell Standards Tests. Brinell Hardness Test • Brinell hardness is determined by forcing a hard steel or carbide sphere of a specified diameter (2.5mm) under a specified load into the surface of a material and .

This results in 30 different Rockwell scales standardized according to ISO 6508 and ASTM E18 (e.g., A, B, C, 30N, 15T) or Rockwell test methods (e.g.: HRA, HRBW, HRC, HR30N, HR15TW), each covering different hardness ranges . The results were as table 1. The Charpy impact test determines the impact toughness or strength of a material by measuring the energy absorbed when a pendulum strikes a V-notched specimen. Testing was .The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the standard completely before attempting a . There are several common hardness tests used to measure this property, including Brinell hardness testing, Rockwell hardness testing, and Vickers hardness testing. Brinell hardness testing involves indenting a .

11. Hardness Testing: Indentation hardness • Brinell Non standard Hardness Test In this test, the loads are decreased and also the ball sizes are reduced. Ball indenters 1.25, 2.5 and 5.0 mm diameters with suitable . 12. BHN is designated by the most commonly used test standards (ASTM E10-14 and ISO 6506–1:2005) as HBW (H from hardness, B from brinell and W from the material of the indenter, tungsten (wolfram) carbide). In former .

HR=[(total load ) scale] = 100 – h/0.001 Where total load is 15, 30, or 45kgH in mm. 6. DEMO PROJECT: CONCLUSION In normal Rockwell based hardness testing machine itoperatedmanually,thetestforceselectionisdone bymanually.Indigital Rockwell based hardness testing machine, It is motorized testing machine which provides automatic operations cycle. 1. Universitas 17 Agustus 1945, Surabaya, 2014 Rohmad Putra 411306092 1 Nama : Rohmad Putra Nbi : 411306092 Kelas : C Rumus Dari Metode Hardness Test Metode Brinnel, Rockwell, Vikers Dan Micro Hardness 1. Metode Brinnel (HB / BHN) Pengujian kekerasan dengan metode Brinnel bertujuan untuk menentukan kekerasan suatu material . 12. ROCKWELL HARDNESS TESTS: - The Rockwell hardness test relies on a specified load and the size of the indentation or penetration made to determine the hardness value. Rockwell hardness tests involve selecting the magnitude of the load to apply based on the suspected hardness of the specimen. Rockwell B (ball) used for soft materials. Rockwell C . 4. Brinell Hardness Test: 10mm diameter ball with a load of 500, 1000 or 3000kg Rockwell Hardness Test: A cone shape indenter; the depth of penetration is measured. Vickers Hardness Test: Pyramid shape indenter ME101: Materials Science and Technology

Hardness - Download as a PDF or view online for free. 13. • 1822: Friedrich Mohs (Ger) - A ten-point scratch hardness Mohs scale. • 1900: J. A. Brinell (Swe) - A ball indentation / dent dia size Brinell Hardness. • 1920: S. R. Rockwell (US) – Minor, major load / dent depth Rockwell Hardness. • 1925: R. Smith and G. Sandland (Eng) – Diamond pyramid indenter / .Rockwell testing falls into two categories: Regular Rockwell testing (e.g., C and B scales) and Rockwell superficial testing (e.g., 30 N and 30 T scales). High Rockwell hardness numbers represent hard materials and low numbers soft materials. d 2 www.wilsoninstruments.com Fundamentals of Rockwell Hardness Testing Rockwell Hardness test A sphere – conical diamond cone of 120º angle and a spherical apex of radius 0.2 mm is used Depth of indentation t is measured. Gradually applied load, Load is applied at right angle to the specimen surface. R = 100 – 500 × t Depending on the load used a scale A, B, C, etc. used. Rockwell test should not be used on .

ecetp are the tests hard

2. Brinell hardness test Brinell Balls Table 1 dia and tolerance of Brinell hardness ball Sr. no Ball dia, mm Tolerance, mm 1 10 ±0.005 2 5 ±0004 3 2.5 ±0.003 4 2 ±0.003 5 1 ±0.003 Measuring Device The divisions of the micro meter scale of the microscope or other measuring devices used for the measurement of the diameter of the indentations shall be such as to .

rockwell hardness testing method

6. = 2 [ − √ − Where: P ; is the test load [ kg] D ;is the diameter of the ball [mm] d ; is the average impression diameter of indentation [mm] The diameter of the impression is the average of two readings at right angles and the use of a Brinell hardness number table can simplify the determination of the Brinell hardness. A well structured Brinell hardness number .

The document describes the Vickers hardness test. It uses a diamond pyramid indenter to make an indentation on the material being tested under a specified load ranging from 5 to 120 kg. The indentation left has a square shape regardless of load. The diagonal lengths of the indentation are measured under a microscope and used to calculate the . Brinell Hardness Testing Method - Download as a PDF or view online for free. Submit Search. . Rockwell hardness test (5) Knoop hardness (2) Brinell hardness (6) Shore (3) Vickers (7) Mohs Hardness (4)Barcol Hardness Brinell Hardness The Rockwell Hardness test is a hardness measurement based on the net increase in depth of impression as a load . The Rockwell hardness test is a fast and inexpensive way to determine the hardness of a material by measuring the indentation left by an indenter applied with a specific force. There are two categories of Rockwell .

ecolab water hardness test kit

Rockwell hardness test measures the permanent depth of indentation on the material by applying a fixed load using an indenter. The smaller the indentation value, the harder is the material. The Rockwell hardness test follows the .The Rockwell hardness testing method fulfilled every requirement. After 100 years, it’s still the best metal strength test method. The Rockwell C scale is also the most precise way to report metal strength used in industrial machine .See also: Hardness. Rockwell Hardness Test. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload .This results in 30 different Rockwell scales standardized according to ISO 6508 and ASTM E18 (e.g., A, B, C, 30N, 15T) or Rockwell test methods (e.g.: HRA, HRBW, HRC, HR30N, HR15TW), each covering different hardness ranges and consequently the widest variety of materials and applications (see table below).

2. ROCKWELL HARDNESS TESTERS MRS MRB MSM MRS-N TRSD-N BRINELL HARDNESS TESTERS AKB-3000 OPAB-3000 OPAB-3000PC OPAB-3000 IPC TEXMO TYPE OPFA-3000 PC VICKERS & MICRO VICKERS HARDNESS TESTERS BV-50 BV-50 IPC HT-1000 ROCKWELL TESTING AIDS www.hardnesstesters.in .The Rockwell scale is one of the standard methods used to measure a material's hardness. The scale has different numbers that represent hardness based on the indent's depth caused by the test material's indentation. Let us look at how you can measure and read Rockwell's hardness value in this article. The Rockwell hardness test uses a diamond or steel ball indenter that is pressed into the material under a minor and then major load. The permanent increase in depth from the major load is used to calculate the Rockwell hardness number. 2. The Brinell hardness test uses a 10mm steel or carbide ball pressed into the material under a 3000kg load .Rockwell Hardness Testing Reference Guide ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your application. Regular Rockwell Testing. In this test method, the minor (preload) is always 10 kgf. .

The document discusses two common hardness tests: the Brinell hardness test and the Rockwell hardness test. The Brinell hardness test uses a spherical indenter that is pressed into the material under a load. The size of the indentation is then measured and correlated to a Brinell hardness number.What is Rockwell hardness testing? The Rockwell Hardness Test is generally a non-destructive test performed on samples when it’s necessary to determine how hard a material is. It’s generally considered easier to perform compared to other methods, like Vickers or Brinell hardness testing. Another advantage is the small area of indentation needed to carry out the . 25. Hardness of Plastics From Matweb: Shore (Durometer) Hardness Testing of Plastics The hardness testing of plastics is most commonly measured by the Shore (Durometer) test or Rockwell hardness test. Both methods measure the resistance of the plastic toward indentation. Both scales provide an empirical hardness value that doesn't correlate to other .

The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the standard completely before attempting a Rockwell test. The Rockwell test is generally easier to perform, and more accurate than other types of hardness testing methods .

rockwell hardness tester least count

Resultado da Watch Breathe: Into the Shadows — Season 1, Episode 1 with a subscription on Amazon Prime Video. Avinash and Abha's life is turned upside down when there 6-year-old .

rockwell hardness test slideshare|rockwell hardness scale examples